From Candy to Eggs

Friday 13 July – Southern tour

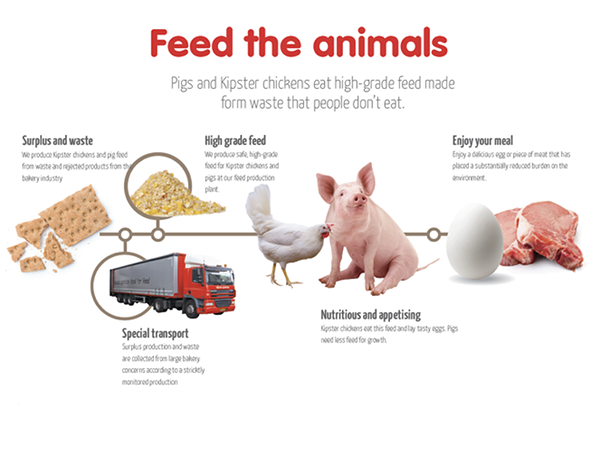

The tour started at Nijsen/Granico. This feed mill factory in the south of the Netherlands isn’t an usual feed factory. They use candy and bread as an important ingredient for producing their animal feed. One of their clients was Kipster, a total new revolutionary chicken eggs concept. They claim to be the most human, animal and environmental friendly chicken farm in the world. Normally the laying hens are producing eggs, but sensational is the ambition to use the cock as well. When these cocks are grown up, Kipster sells them to supermarkets. We visited this supermarket where they sell the eggs. The lunch in the afternoon was provided by Nijsen/Granico.

Nijsen/Granico

The company started processing surplus foodstuffs from the food industry to make semi-finished products for the manufacture of animal feeds in 1989. At first mainly dough-based products were recycled. Once this was found to have very positive results, the range of products used was quickly expanded to include biscuits and sweets and so on. New surplus products to be processed into animal feeds are still being added today.

In terms of nutritional value, food safety and environmental aspects, the processing of food surpluses is completely safe. The processes are continuously monitored by the quality assurance system in place. This system is based on the GMP (Good Manufacturing Practice) code formulated by the Dutch regulatory organisation, the Product Board Animal Feed. Nijsen/Granico has been in possession of a GMP certificate for both its Food and Feed divisions since 1 February 2001.

Food-for-Feed concept

Nijsen/Granico has been in possession of a GMP certificate for both its Food and Feed divisions since 1 February 2001. Nijsen/Granico Food also guarantees that your food surpluses are safely processed into animal feeds.

In terms of nutritional value, food safety and environmental aspects, the processing of food surpluses is completely safe. The processes are continuously monitored by the quality assurance system in place. This system is based on the GMP (Good Manufacturing Practice) code formulated by the Dutch regulatory organisation, the Product Board Animal Feed. The code is derived from the NEN-EN-ISO 9002 norm.

Food

The system can be made to fit within the HACCP standard you use. So your GMP-certified surpluses are safely disposed of and processed, and certainly add value to animal feeds.

Hygiene plays a very prominent role in the transport, storage and processing of surpluses. Checks for any microbiological contamination are carried out regularly. This is why, for example, our pallet boxes are thoroughly washed after each use. It is also from a hygiene point of view that we ensure that products are processed as quickly as possible, on a First-In-First-Out basis. Products which are highly perishable are given priority.

Feed

Through its Food-for-Feed concept, Nijsen/Granico replaces some of the usual ingredients in animal feeds with very tasty, easily digestible food ingredients. This leads to a high intake of feed, resulting in healthy animals that are full of vitality. High feed intakes plus healthy animals equals high production rate.

Nijsen/Granico in an egg shell

- Nijsen/Granico is relatively small feed company in the Netherlands.

- The food-for-feed concept is unique in the world.

- The feed mill company is family owned business.

- Nijsen/Granico is focusing on feed production for pigs and Kipster.

Kipster

Kipster claims it’s the most animal-friendly and environmentally- friendly poultry farm in the world.

Animal friendly

Kipster imitate a natural wooded environment for the chickens. There is plenty of variety, daylight and fresh outdoor air inside. The indoor garden has been set up as a playground for the chickens In the park, there is a lot for the chickens to experience due to the varied planting.

Environmentally friendly

Kipster use an extremely low ammonia standard of approximately 0.025 kg per chicken. The reduce the fine particle emission to more than 90%. The chicken feed originates from residual flows and does not compete with food which could also be suitable for human consumption 1,078 solar panels on the roof supply more energy than they use. The only use electrical facilities and do not use fossil fuels.

No unnecessary kilometres: the eggs are packed on the farm and delivered directly. The farmer receives a fair price from Lidl for the eggs, and the consumer pays Lidl a fair price. There is room for visitors and a centre for education and information. When our chickens ‘retire’, they are not dumped in Africa to disrupt the market there, but they are processed here into high-quality meat products.

Lower disease pressure

The park is fenced off and covered with a net, which considerably reduces the danger from other birds and animals. In the case of bird flu, the consequences are less serious than with other free range systems. The excellent air quality on the farm is good for the farmer and his chickens.

The plan for planting around the farm is part of the design. All the technical installations and silos are out of sight. The design is aesthetic and functional.

The farm is an alternative to conventional agriculture. The concept can be made suitable for urban agriculture. Thanks to the modular set-up, farms with 3,000 to 96,000 chickens are possible.

Kipster in an egg shell

- Kipster is owned by 4 owners: Styn Claessens, Ruud Zanders, Maurits Groen, Olivier Wegloop

- The farm is opened at October 2017.

- There about 24.000 laying hens.

- The egg production is enough for supply the half of the Dutch Lidl supermarkets.

- The egg received the maximum of three stars of the animal welfare organization.

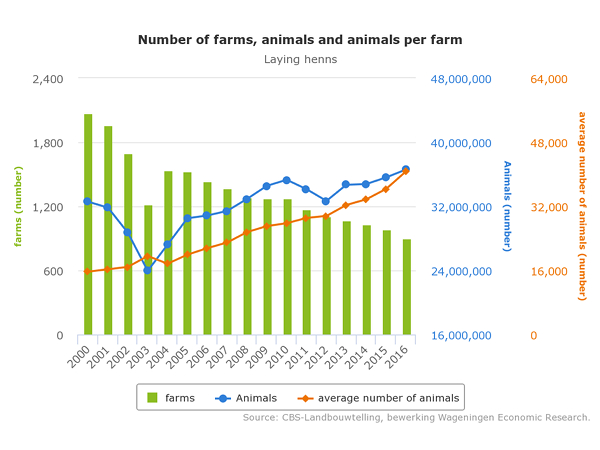

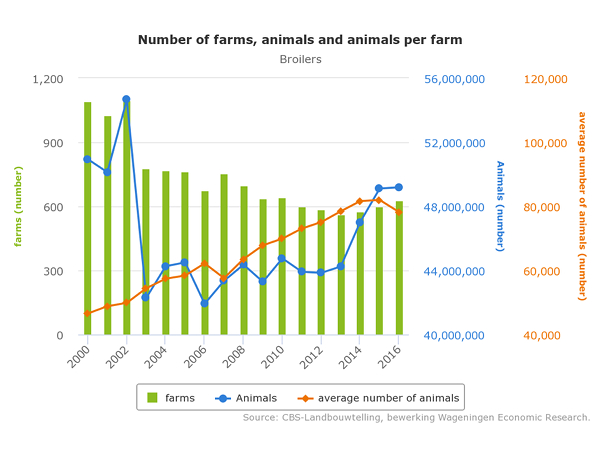

Facts and figures Dutch poultry sector

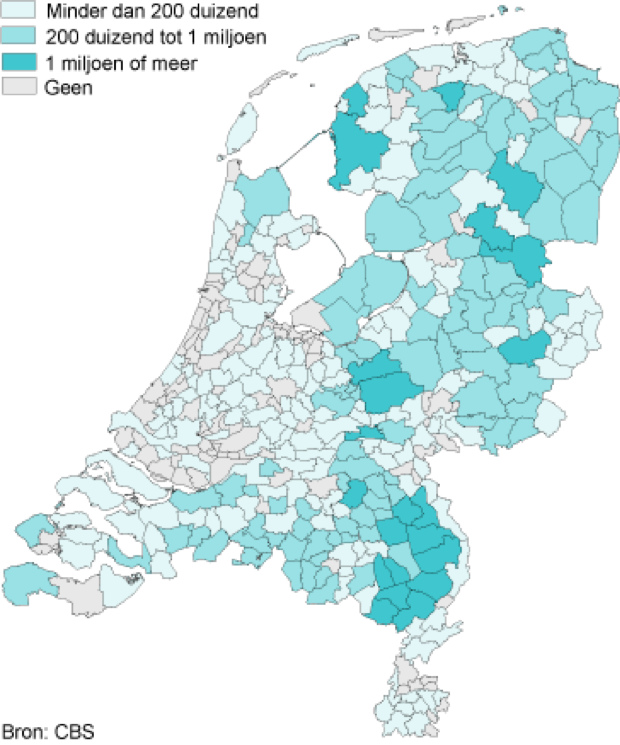

Where are the chicken?

(The figure is showing the number of chicken in every region)

Dutch poultry sector in an egg shell

- There about 107 million chicken in the Netherland: 48 million broilers and 35 laying hens.

- Chicken is the most eaten meat in the Netherlands. Dutch people eat about 18 kg chicken each year.

- Dutch people eat about 200 eggs a year, 60 – 70 % is direct egg consumption.

- The production value of export Dutch eggs is € 448 million.