Sustainable Cropping Systems

Friday 13 July – Northern tour

Dutch crop growers are masters of efficiency. This tour first brought us to the Flevopolder, the biggest land reclamation in the world, where a hectare of land cost over 100.000 euro per ha. We visited two farmers with different approaches to get the most out of their land and at the same time keep the soil in good condition. We then crossed the dyke to Enkhuizen to visit Syngenta’s state of the art breeding station, where we got a unique insight in modern plant breeding for future crops.

Arable farm Leo and Willemien de Jonge

Leo de Jonge and his wife Willemien Verbeek farm 170 ha of arable crops (cereals, potatoes, onions, tulips and grass) in Zeewolde. They have four children, in the ages 14-19. Are they potential farmers? “We don’t know yet. There is a lot more to do in the world than only farming. But, they are interested in farming, so we shall see what the future brings! We hope they will explore the world, have fun and work hard.”

History

Leo’s parents started farming on the home farm in Zeewolde in 1980. They were the first to work the virgin land, which was reclaimed from the sea in the sixties by the Dutch goverment. Until 1997 they farmed 60 hectares, growing potatoes, sugarbeets, wheat and onions.

When Leo took over the farm he started renting land at neighbouring farms, to be able to grow more potatoes and onions. Around the same time, the farmers in The Flevopolder were given the opportunity to buy the land they had leased so far. Leo first bought half of the farm and this turned out to be a solid base for further development of the farm.

In 2004 Leo and Willemien bought their second farm, in Biddinghuizen (20 km away from the home farm). This was a big step and made them owner of 119 ha of land (and a big debt, they add…). The years after 2006 were difficult, with as little investments as possible. They slowly recovered and in 2011 they built a new onion storage.

Dairy

Leo and Willemien work together with six other farmers, exchanging land and labour. This enables them to grow more potatoes and onions. They grow grass and other feed crops in their own cropping plan and also use manure. This is important to keep the soil in good condition. They’ve exchanged land with the direct neighbour (a dairy farm) for decades. In 2015 the neighbour stopped farming and Leo and Willemien took over the farm and the land, adding an extra 53 ha and 75 milking cows to their farm business. They’ve now started milking the cows with a dairyfarm manager.

Soil health

Soil health is an imporant issue in The Flevopolder. Eventhough it is one of the best soils in the world, there’s heavy pressure on the land, with intensive rotations. Leo participates in Stichting Veldleeuwerik (Skylark foundation www.veldleeuwerik.nl/en ) where he exchanges knowlegde with a group of collegues, mainly focussing on soil health.

Other activities on the farm are: 1 Windmill 900 kW, renting out 1 windmill location, spraying maize and grass.

Figures De Jonge farm

Land: 172 ha owned (166 workable) +21 ha yearly leased

Soil: clay soils and sandy clay soils with high chalk pH 7,5, organic matter 2-5 %

Storage facilities: 7,000 ton of potatoes and onions

Crops:

- 73 ha Potatoes (for french fries: Agria, Victoria, Innovator)

- 7 ha Seedpotatoes

- 39 ha Onions

- 40 ha Sugarbeet (+ 32 ha contract work, except harvest)

- 12 ha Wheat (+ 15 ha contract work)

- 15 ha tulips rented out (+ contract work on 41 ha)

- 23 ha grass, 1 and 2 year old grass in rotation, for making silage

- 4 ha silage corn

Bio Brass

Bio Brass is active in growing, processing and marketing of organic vegetables. The farmers who initiated the company joined forces to jump into the demand for sustainably produced food directly from the farm. On Flevoland’s young, fertile soils they grow and process organic vegetables on a large scale, and directly deliver to the retail. Their first focus was on kale; hence the name Brass, referring to ‘brassica’.

Bio Brass is able to produce a stable and continuous volume of products for its buyers, who are based in The Netherlands, UK, Germany and Scandinavia. Vegetables are processed and packed on site, making it possible to avoid any unnecessary costs and quality losses further on in the chain. This makes Bio Brass a unique chain partner for initiating or strengthening the organic vegetables category.

Growing

On about 250 hectare Bio Brass grows cauliflower, broccoli, other cabbages, celery, parsnip and various lettuces, all within an extensive crop rotation. The scale and specialisation is made possible by collaboration with other growers, with a combined acreage of 2.000 ha. One of the rotation partners is BV Erf, the largest private organic farm in The Netherlands, and also shareholder in Bio Brass.

In the eyes of the founders of Bio Brass, sustainability goes beyond organic farming practices alone. “We think from field to food shelves”, managing director Gerjan Snippe explains. The products are often processed and packaged on site, during harvesting and on the field whenever possible. This avoids unnecessary costs, ensures the product spends less time on the road and residual flows can be used as, for example, cattle feed.

Inspiring

Snippe and his collegues enjoy sharing their vision and passion behind their farming method with customers, consumers, policymakers, students, pupils and anyone else who is interested. They have produced a small-scale replica of the large-scale activities happening out on the field. “In our experience garden we spend time together to look, talk, feel, smell and particularly sample. It is the ideal way of explaining why organic farming is anything but complicated and produces beautiful, healthy, affordable and delicious vegetables.”

Syngenta Seeds

Located in the middle of the area known as the Seed Valley, the Syngenta Enkhuizen R&D site is one of biggest seeds production sites in the industry. With over 36 million euros invested in recent years to expand the site, and thanks to the newborn Technology Center space, it actually offers the most advanced technologies available in a modern facility. For the first time journalists are invited to have look.

Biotechnology

Throughout a real journey we discovered the technologies and innovation used to increase vegetable yield and quality to meet the growers needs adapting to the consumers’ needs. We learned about the company’s view on sustainable crop growing and got a brief introduction to new technologies and the role they play, or can play in future. Syngenta’s breeders introduced some of the latest breeding techniques and shared a real case study to better understand what innovation stands for in seeds development and what are the real advantages for the entire value chain.

Tour site

We then put on our coats and started the plant visit and had the chance to see how the seeds are processed when coming from the field and we followed the steps into the packaging phase. The journey continued to discover the new glasshouses of the Technology Center where we learned how the new facilities can help to improve the R&D practices in seeds development. At the end of the tour we were offered a vegetable produce demo/tasting session.

Dutch roots

In 2017 Syngenta celebrated 150 years in the vegetable seed industry. A great example of Dutch Roots: Sluis and Groot, a legacy company of Syngenta, was founded in 1867 in the Netherlands as exporters of cabbage seeds. Today, Syngenta is one of the world’s leading vegetable seeds companies with 30 crop species and 2,500 varieties.

Facts & figures about Dutch arable farming

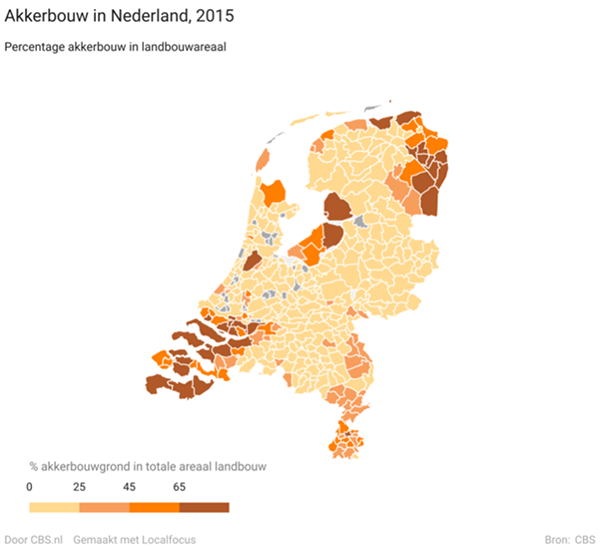

Where is the arable cropland?

(The figure is showing arable land as a percentage of total farm land)

Dutch arable sector in a nutshell

- The Netherlands has 12,000 arable farmers (definition: more than 2/3 of the turnover comes from arable farming), of which 9,000 are pure arable,

- A quarter of the agricultural land in the Netherlands is in use as arable land: about 500,000 ha. The average size of an arable farm is 42 ha,

- 8% of the arable farms is bigger than 100 ha. They account for 37% of the acreage,

- More than 30% of the arable land is used for potatoes,

- The average price of farm land in the Netherlands is 56,500 euro per hectare. (In Flevoland, where the two farms of this tour are located, prices are 80,000 up to 120,000 euro per ha),

- The Dutch farming sector exports 2/3 of its production,

- The Netherlands is the biggest exporter of seed potatoes, onions and flower bulbs in the world.

A little history of Flevoland

After a flood in 1916, the Dutch gouvernment decided that the Zuiderzee, an inland sea within the Netherlands, would be enclosed and reclaimed. In 1932, the Afsluitdijk was completed, a 32 km dyke which closed off the sea completely.

In between 1940 and 1968 the red area became new land. The municipalities on it voted to become a separate province, which happened in 1986. This makes Flevoland the youngest province of the Netherlands. The province is on average 5 m below sea level.

Agriculture

All of the landscape in Flevoland has been designed on the drawing board, planned en developped by the State, and is very rational/functional.

First the Noordoostpolder (48.000 ha) became ready. Blocks of 24 ha (300 x 800 m) were formed and farms were made in sizes of 12, 24, 36 and 48 ha. The first farms were ready in 1947. To keep the costs down, the houses and the barns were made identically. Villages were carefully planned, and little rows of houses for farm workers were spread out over de polders.

Last came Southern Flevoland (this is where the farms are located that we’ll visit). The last water was pumped away in 1968. The invention of PVC-pipes for drainage made it possible to make the parcels 500 m wide. Here a typical farm originally is 60 ha (1,200 x 500 m).

Not only the landscape was designed. Also the people were carefully selected in a way that they reflected the other parts of the Netherlands, in background (provinces and religion). Inspectors of the National Government even visited the candidates at their home farm on the ‘old land’, to see if they were a good farmer, the house was clean (some say they even looked inside the kitchen cabinets), they had a healthy financial position and to see whether they were socially involved.

A lot of young farmers were eager to go to the Flevopolder, to the ‘promised land’, with its rich soils and square, large and well-drained fields. And also for the adventure to build up a new community and make the best of it.